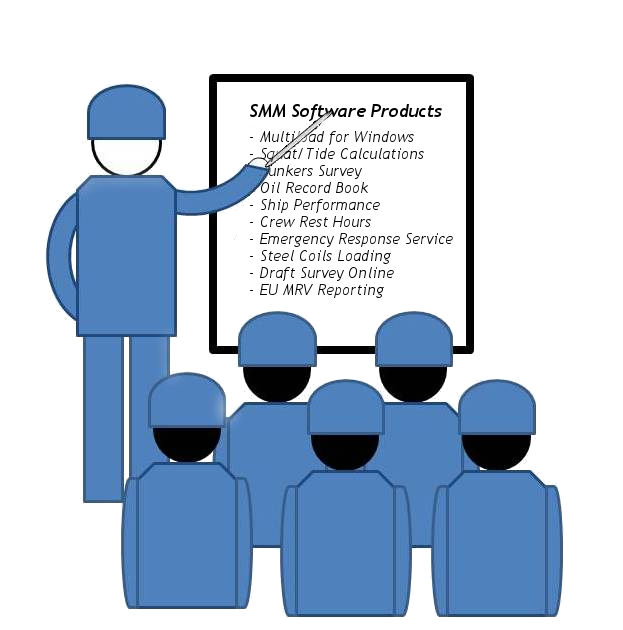

Bunker Survey Calculation Software

Shining armour, I bought a Samsung DVR and smartviewer 2.0 from a. Start by going to the Samsung website and download the user guide. SmartViewer is a complementary video management software that enables streamlined management and control of Wisenet Devices via the network. Samsung Techwin's free software for DVR. Provided DVR: SRD-XXXX series. CCTV Systems and CCTV Cameras.

Finally, I have comfort time to complete this post after having busy with some surveys that I should fulfil. Any terms on this post should be refer to previous post Draft Survey: Terms of Conduct.

Quantity delivered calculation, based on density testing. Detailed bunker survey reports. Sampling documentation photographs as requested or permitted. Intertek's marine bunker fuel surveying services are supported by experienced bunker fuel quality testing laboratories. Marine bunker fuels are tested to ISO 8217, Marpol Annex VI and other specifications. Bunker fuel samples are easily packaged and shipped for testing on a global basis, as needed, through the ShipCare program.

The Draft Survey procedures and calculation ascertained as the following series :

Bunker Survey Calculation Software

- Reading the draftmark of the ship, which consist of six (6) points of draftmarks, i.e.; Fore, Midship, and After at both sides of the ship,

- Sampling and testing the sea water or dock water density at the place where the vessel floats,

- Determining of deductible weights by measuring and sounding of ballast tanks, fuel oil, fresh water that existing onboard at the time of survey,

- Using Hydrostatic Table provided onboard to begin calculation.

- The bunker calculation is simple and needs the following: - Tank Sounding data and Tank Capacity Table. The Corrected Sounding means below is the sounding after correcting with vessel’s trim and list.

- Bunker Survey Calculation In my last post How To Conduct Bunker Survey.60. Download available at you could try the software 7s-BunkerCal.

Reading the Draftmark of the ship

Commonly, all ship are designed with draftmark for working with Draft Survey to determined their actual weight. The draftmark could be find at six (6) points on the below places:

- Forward Port Side (FP),

- Forward Starboard Side (FS),

- Midship Port Side (MP),

- Midship Starboard Side (MS),

- Aftward Port Side (AP),

- Aftward Starboard Side (AS),

View the Draftmark:

Use the small boat to go around the ship and get as near as possible to the draft mark for best viewing. The surveyor should be read all above marks clearly, because reading the draftmark is the first and most essential process. I am not saying that other processses is not essensial, but this process is hard to do and involves many rules of conduct to gain the correctness and accuracy of Draft Survey itself (I will post it later). The draftmark read is recorded on the surveyor notebook, do not try to remember it or write down in your palm hand. Its useless and un-professional.

Sampling and testing the sea water or dock water density

After reading the draftmark, directly engage with the sampling of sea water or river water around the ship’s dock. Why? Because the ship draft will not be the same at different water densities (at the lower density means the ship more sink and at the higher density means the ship more float). Where as the water density is subject to changes which follow with water tide that carrying different water salinity and temperature on to the ship dock. The sea water density is indeed at density 1.025 and the fresh water at density 1.000. To determine the density of water, we need the instrument named Hydrometer or Density Meter. Inserted the Hygrometer on to the water sample on the Sampling Can or Tube, then we could check the scale pointed on the surface of the sampling water. Records the water dock density as survey data.

Determining of deductible weights by measuring and sounding

Deductible Weight could measure by sounding the tanks which used the Sounding Tape or gauging the tank level by visual inspection. Any deductible weight such as Ballast Water, Fresh Water, Fuel and Diesel Oil, and Bilges is notify to check. Records all in the survey book includes with the density for Ballast and Bilges, and for Oil complete it with density and temperature . The Fresh Water was at density 1.000.

View the Sounding Pipe:

Using Hydrostatic Table provided onboard to begin calculation,

I think all necessary data was completed, so we could do calculation. The calculation is uses Displacement Table or usually called Hydrostatic Table. This table is included all data that we need to complete the calculation.

- Raw Draft Calculation; Fore Mean or Fm = (FP+FS)/2, Mid Mean or Mm = (MP+MS)/2, and Fore Mean or Am = (AP+AS)/2. while Apparent Trim or AT = Am – Fm. the Apparent Trim is the Trim that visually find.

- Draftmark posision and correction to perpendicular. As the ship draftmark is not placed at the perpendicular, the Fore and After draft should be corrected with distance from the draftmark to perpendicular. The correction rules is: if the Trim by Stern, the Fore correction should be minus and After correction plus, and if the Trim by Head (stem), the Fore correction should be plus and After correction minus. The Midship correction is parallel with the fore correction with the same pattern. Some Hydrostatic table provided with these correction result. But if not the reference pattern is for Fore Correction or Fc = (Fd x AT) : LBM and After Correction or Ac = (Ad x AT) / LBM. Where Fd = Fore distance to perpendicular, Ad = After distance to perpendicular, and LBM = Length Between Markor Length between Fore and After draftmarks or LBM = LBP – (Fd + Ad).

- True Draft Calculation / Draft Corrected; Fore draft corrected or Fcd = Fm + Fc, Mid draft corrected or Mcd = Mm + Mc, and After draft corrected or Acd = Am + Ac.

- True Trim or TT : Actual Ship Trim after draft corrected or TT = Acd – Fcd.

- Fore and After Mean Draft or FAm = (Fcd + Acd)/2, Mean of Mean Draft or MM = (FAm + Mcd)/2, and Mean of Mean of Mean Draft or MMM or Quarter Mean = (MM + Mcd)/2.

- The above calculation is similar with : MMM = {(Fcd x 1) + (Acd x 1) + (Mcd x 6)}/8.

- Coresponding to the MMM or Quarter Mean result, the surveyor could check the value of needed parameters on Hysdrostatic table like; Displacement, TPC, LCF, and MTC. Records them accurately.

- First Trim Correction or FTc = (TT x LCF x TPC x 100) / LBP. Could be plus or minus depend on LCF.

- Second Trim Correction STc = (TT x TT x MTC x 50) / LBP. The result always plus (+).

- Displacement corrected by Trim or DispT = D – (FTc + STc).

- Density Correction or Denc = DispT x {(Aden – 1.025) / 1.025}. where the Aden is Actual Density that surveyor has taken sampling and testing previously. The density correction commonly in minus (-), due to the Actual Density is usually lower than 1.025 (fresh sea water). In case of at some port where the water salinity is high, the density correction could be plus (+).

- And we have got the Displacement corrected by Density or DispDenc = DispT + Denc. (after corrected by density we will get the actual ship weight as per shown by Draft Survey)

- Deductible Calculation. The same as draft, the deductible also need to corresponding to the table that named Tank Table / Tank Capacity Table. Refer to the sounding records that done before, the surveyor could be calculate the total deductbile existing onboard. Total Deductible or Deduct = Ballast Water + Fresh Water + Bilges + Fuel Oil + Diesel Oil, this total should be minus to the Displacement corected by Density.

- The Net Displacement or NDisp = DispDenc – Deduct.

- The Net Displacement is the actual ship weight after minus with deductible weight. For Unloading, to estimate the quantity of cargo onboard, the Net displacement should be minus with Light Ship and Constant.

I think difficult for the amateur writer like me to describe the complex narration of draft survey calculation, but to make it clear, the sample of Draft Survey Calculation will be post sooner or later. 🙂

- Easily used by ships maintenance staff right out of the box

- Instant indication of condition for motor bearings, gears, compressors, slewing rings, hoists, winches..

- Plan maintenance and have the spares available on time. Minimise off-hire and demurrage.

Whatever the method of fuel oil delivery, it is possible to determine the volume received on the vessel by taking a sounding or ullage of the receiving tanks.

By making allowance for the vessels trim and or list the volumes can be calculated. At first sight this would appear to be an accurate method of determining the fuel oil volume received, but in reality it is frequently not the case. This is because of the size of the tanks involved, possible inaccuracies in the calibration tables and the difficulty of accurately correcting for trim or list.

Fuel Oil Delivery from Shore Side Tanks

When delivery is received from shore side tanks, the above method may be the only way of estimating the volume received. A better method would be the witnessing of the soundings/ullages of the bunker fuel storage tanks at the beginning and end of delivery. In all probability, it is not possible for the Chief Engineer or a member of ship’s staff to gauge the shore tanks and establish if pipelines were empty or full before and after the bunkering. The only practical way is to appoint a surveyor who has access to the tank and who will be able to carry out the pipeline calculations. Sometimes volume meters are available, but there is no practical way of verifying that meter readings are correct.

Fuel Oil Delivery from Road or Rail Wagon

Road or rail wagon deliveries occasionally take place. In general, these are usually related to distillates, with the fuel measured by a meter.

Delivery by Barge

When making an accurate bunker fuel quantity determination, it is necessary to take the temperature of the bunkers both at the beginning and end of delivery so that volumes can be corrected back to the standard temperature of 15°C. This applies to shore tanks, road or rail wagons and also a barge delivery.

| Table A | |||||

|---|---|---|---|---|---|

| Temp °c | >982 | >984 | >986 | >988 | >990 |

| 40 | 0,9827 | 0,9827 | 0,9828 | 0,9828 | 0,9829> |

| 41 | 0,9820 | 0,9820 | 0,9821 | 0,9821 | 0,9822 |

| 42 | 0.9813 | 0,9813 | 0,9814 | 0,9814 | 0,9815 |

| 43 | 0,9806 | 0,9807 | 0,9807 | 0,9808 | 0,9808 |

| 44 | 0,9799 | 0,9800 | 0,9800 | 0,9801 | 0,9801 |

| 45 | 0,9792 | 0,9793 | 0,9793 | 0,9794 | 0,9794 |

| 46 | 0,9785 | 0,9786 | 0,9786 | 0,9787 | 0,9787 |

| 47 | 0,9778 | 0,9779 | 0,9779 | 0,9780 | 0,9780 |

| 48 | 0,9771 | 0,9772 | 0,9772 | 0,9773 | 0,9774 |

| 49 | 0,9764 | 0,9765 | 0,9765 | 0,9766 | 0,9767 |

| 50 | 0,9757 | 0,9758 | 0,9758 | 0,9759 | 0,9760 |

The following example relates to a barge delivery, but the principle can equally be applied to other forms of delivery:For each tank, the opening soundings or ullages are taken along with the temperature of oil in the tank

- From the barge calibration tables, the observed volume can be determined

- The volume at 15°C is then determined by applying the volume correction factor (VCF) given in Table 54 of ISO 91-1. Table A shows an extract of Table 54B from this standard

- In order to determine the VCF, the density of the product being delivered has to be known

At this stage, the only figure available is that stated by the supplier on the Bunker Delivery Note.

| Table B | |||||

|---|---|---|---|---|---|

| Tank m | Sounding | Temp ° | Observed Vol m3 | VCF | Vol at 15° m3 |

| 1P | 3.01 | 48 | 106.135 | 0.9773 | 103.725 |

| 1S | 2.99 | 48 | 105.529 | 0.9773 | 103.135 |

| 2P | 3.339 | 48 | 171.026 | 0.9773 | 167.144 |

| 2S | 3.39 | 48 | 170.958 | 0.9773 | 167.077 |

| 3P | 3.37 | 48 | 172.048 | 0.9773 | 168.143 |

| 3S | 3.38 | 48 | 172.357 | 0.9773 | 168.444 |

| 4P | 3.20 | 48 | 168.812 | 0.9773 | 164.980 |

| 4S | 3.23 | 48 | 169.893 | 0.9773 | 166.036 |

| 1236.758 | 1208.682 | ||||

Table B shows the opening readings, before discharge, of the barge, the stated density of the product being 990kg/m3. From this it may be seen that the total observed volume is 1236.758m3. This relates to the standard volume at 15°C, which is 1208.682m3. The VCF is taken from Table 54B for the measured temperature.

| Table C | |||||

|---|---|---|---|---|---|

| Tank | Sounding m | Temp °c | Observed | VCF Vol m3 | Vol at 15°c m3 |

| 1P | MT | ||||

| 1S | MT | ||||

| 2P | MT | ||||

| 2S | MT | ||||

| 3P | 1.41 | 46 | 71.964 | 0.9787 | 70.431 |

| 3S | 1.43 | 46 | 72.985 | 0.9787 | 71.430 |

| 4P | MT | ||||

| 4S | MT | ||||

| 144.949 | 141.861 | ||||

The total volumes delivered by the barge, both for observed and standard temperatures, can be found by subtracting the closing volumes from those at the start: The observed volume transfer = 1236.758 - 144.949 = 1091.809 m3.

The standard volume transfer = 1208.682 - 141.861 = 1066.821 m3.

| Table D | |||||

|---|---|---|---|---|---|

| Density at 15°c Kg/m3 | Factor for converting weight in vacuo to weight in air | ||||

| 841.2 to 903.4 | 0.99875 | ||||

| 903.5 to 975.6 | 0.99885 | ||||

| 975.7 to 1060.4 | 0.99895 | ||||

As already defined, density is the absolute relationship between mass and volume and not its weight to volume, by definition density is in vacuo. To convert weight in vacuo to weight in air, reference must be made to Table 56 of ISO 91-1. An extract of this table is shown in Table D.

The theoretical weight transferred in air: = Density (kg/m3) * Standard volume at 15°C (m3) x Factor = kg * kg/1000

= (MT) = 990.0 x 1066.821 x 0.99895

= 1055043.7 kg = 1055.044 MT

The value of 1055.044 MT represents the weight of fuel transferred in air, based upon the density given on the BDN. In order to determine the actual weight transferred, the density of the fluid delivered must be determined. This determination can either be by on-board testing or after laboratory analysis.

Assuming that the density determined from a representative sample of the bunkering is 985.1 kg/m3, the actual weight transferred in air:

= 98.51 * 1066.821/1000 * 0.99895 = 1049.82 MT

If the density is not determined from a representative sample, the BDN should be signed only for volume. If the supplier insists on a signature for weight, add “for volume only - weight to be determined after density testing of a representative sample”.

Comment:

The example calculation given for a fuel delivery changed the actual delivery from:

Opening Closing 1224.39 - 144.949 = 1079.44 Changes to 1049.82 MT a saving of 29.62 MT or $14810 at $500/MT

Off-line Bunker Fuel

- Offline Bunker Fuel

- Bunkering

- Delivering

- Bunkering